Aluminium beverage can is popular in drink packaging industry. From 1950s, there are some companies use aluminium alloy for packing drink. Recent years, the manufacturing technologies are improved. The aluminium beverage cans weight is decreasing. Meanwhile, using aluminium sheet for beverage cans making, it is environmental. Because the aluminum beverage cans are recyclable. Wanda can provide you aluminium alloy sheets for your beverage cans manufacturing needs. And there are different aluminium alloys, thickness and sizes for you to choose.

How to use aluminium sheet for beverage can making?

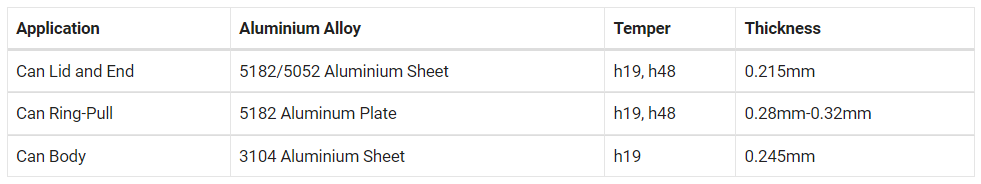

Making aluminum beverage cans, there are many different aluminium alloys you can choose. For the different parts of cans, you can choose different aluminum. You can choose it according to your own requirements. For example, if you want to pack the sodas, you had better use our 5182 aluminum alloy sheets for can lids making. Its is more suitable than the 5052 alu alloy plates. Besides, for your can body making, we will recommend the 3104 aluminum alloys.

5182 aluminium sheet and 5052 aluminum for can lid

5182 alu is belongs to 5000 series aluminium. It has similar properties with the 5052 aluminum alloy plates. These two aluminium alloys are applicable for you to produce can lids and ends. In Wanda, we have six machines for checking the cleanness of finished 5182 and 5052 aluminium sheets.

And our use ratio of can lids stocks are higher than other factories. Meanwhile, because of the special use of can lids and ends, we use environmental coating when manufacturing. It makes sure the safety of our can lids stocks.

5182 aluminum alloy for can ring-pull tab

Making can ring-pull tab, the 5182 aluminum sheets is an ideal choice. It has more magnesium content than 5052 alloy sheet. And there are some silicon content added in 5182 aluminum alloy. Thus, the weld-ability of 5182 is better, too. Generally, our customers choose 5182 h19 temper and 5182 h48 aluminum for ring-pull producing.

3104 aluminium plates for can body making

3104 aluminum alloy is a kind of 3000 series aluminium manganese alloy plates. It has medium strength, excellent impacting, form-ability and ductility. Using 3104 h19 for can body manufacturing, decreasing the materials consumption.

What are the benefits of using Wanda aluminium for beverage can making?

Using aluminium sheet for beverage can making is popular in the market. For your beverage can making business, you can choose our aluminium sheets. Here are some reasons for your reference.

- The aluminium sheets have light weight. For your packaging needs, the light weight materials is helpful for reducing the overall weight of the beverage can. Meanwhile, it is more convenient for transporting.

- Aluminium sheet is corrosion resistant and rust resistant. As we know, the drinks are liquid. Using aluminium sheet for packing, the can body will not be rust or corrode. And the aluminium alloys we provided for your beverage can making are food grade. It makes sure the safety and hygienic.

- It is recyclable. Aluminium is recyclable. And the aluminium beverage cans can be recycled and reused. Thus, the aluminium alloy beverage cans are environment friendly.

- Aluminum alloy sheets are easy for you to shape it. It is applicable for your aluminium beverage cans manufacturing.

How does Wanda Pack the Aluminium Sheet and Coil Products?

Purchasing aluminium sheets and coil rolls from Wanda, you do not need to worry about the goods’ quality. Generally, we choose shipping for transporting. There may be some cracks. While, choosing Wanda Aluminium, there will be no problems during the transportation. Because we apply high configured packing materials for making sure the steadiness, flatness and good surface. You can get the high quality goods with no cracks.

- We utilize protective film and paper for protecting the surface of aluminium sheets and coil rolls. At the same time, there are also plastic or kraft paper for wrapping the products, which is helpful for moisture proofing and rain proofing.

- Before we put the packed aluminium sheets and coil into the container, we use the wooden pallet for strengthening the wrapped aluminium products. Meanwhile, there are also steel belt, which can also improve the steadiness and avoid collision. For your information, our wooden pallets are also marked with fumigation.

- Our company put the dryer agent into the containers. It is helpful for avoid the goods being moist, making sure the quality.

| Application | Aluminium Alloy | Temper | Thickness |

|---|---|---|---|

| Can Lid and End | 5182/5052 Aluminium Sheet | h19, h48 | 0.215mm |

| Can Ring-Pull | 5182 Aluminum Plate | h19, h48 | 0.28mm-0.32mm |

| Can Body | 3104 Aluminium Sheet | h19 | 0.245mm |