Aluminium roofing sheet is a new roofing sheet, which is environmental. It is popular used in villas, self-built houses, shopping malls building, street transformation and so on. Using aluminium for roof making, the roofing sheets have light weight. And its structures are simple. Meanwhile, it has excellent weather resistance. Whether for the heat expansion or the cold contraction, the damage will be little. Especially, its service life is long, which can achieve about 50 years. Thus, you do not need to maintain it often after the installation. For your roof manufacturing business, our aluminium sheets are your ideal choices.

Why use aluminium for roof making rather than color steel?

With the rapid development of the society, utilizing the metal for roof making is a trend. There are galvanized steel sheet, stainless steel, aluminium alloy, copper, pure titanium plate, etc. The metal sheet has good waterproofness. And it is recyclable. Besides, the metal roofing sheet has little deformation. Here are some information about the color roofing plate and aluminium roofing sheets.

- The aluminium manganese alloy sheets has longer service time than some the color steel sheets. Under the wet circumstance, there will be some rust and splitting if you use the color steel for roofing sheet making. While, the aluminium can avoid it.

- Generally, the aluminium roofing sheets are lighter than the color steel ones. Because the density of aluminium manganese alloy is about 2.73g/cm³, and the color steel is about 7.85g/cm³.

- The aluminium alloy has lower melting point. Once there are some accident, it can help release the fire. So that the fireman can use the fire main conveniently.

- The weldability and plasticity of aluminium are excellent. And with low temperature, the strength and ductility of aluminium roofing sheet will be improved. While, under the same low temperature, the color steel roofing sheets will be more fragile.

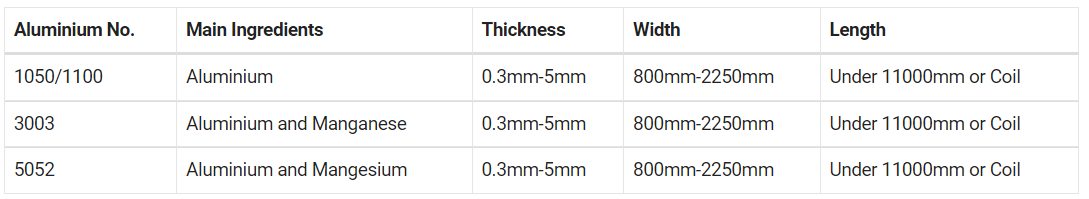

Which aluminium are applicable for your aluminium roof sheet making business?

Making aluminium roofing sheets, it is applicable for you to choose the 1000 series pure aluminium or our 3003 aluminium manganese alloy sheets. Generally, our 3003 aluminium alloy are popular for roof making among our customers. Its strength is higher the 1000 series pure aluminium, including 1050 aluminium, 1060 aluminum and 1100 aluminum. And its rust resistance is better, too. Because there are more manganese content in 3003 than 1000 series aluminium. While, you can use 1050 or 1100 aluminium sheets for your roof sheets producing, if you have less requirements on the strength and bending properties. Because the pure aluminium sheets has more economic prices than aluminium manganese alloy. For your reference, there are also 5052 aluminium for your architecture with maritime climate in Wanda. Our 5052 aluminum alloy sheets has better corrosion resistance.

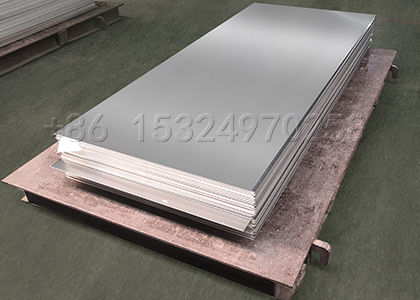

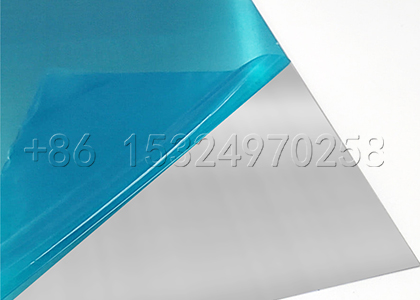

How does Wanda Pack the Aluminium Sheet and Coil?

Purchasing aluminium sheets and coil rolls from Wanda, you do not need to worry about the goods’ quality. Generally, we choose shipping for transporting. There may be some cracks. While, choosing Wanda Aluminium, there will be no problems during the transportation. Because we apply high configured packing materials for making sure the steadiness, flatness and good surface. You can get the high quality goods with no cracks.

- We utilize protective film and paper for protecting the surface of aluminium sheets and coil rolls. At the same time, there are also plastic or kraft paper for wrapping the products, which is helpful for moisture proofing and rain proofing.

- Before we put the packed aluminium sheets and coil into the container, we use the wooden pallet for strengthening the wrapped aluminium products. Meanwhile, there are also steel belt, which can also improve the steadiness and avoid collision. For your information, our wooden pallets are also marked with fumigation.

- Our company put the dryer agent into the containers. It is helpful for avoid the goods being moist, making sure the quality.

| Aluminium No. | Main Ingredients | Thickness | Width | Length |

|---|---|---|---|---|

| 1050/1100 | Aluminium | 0.3mm-5mm | 800mm-2250mm | Under 11000mm or Coil |

| 3003 | Aluminium and Manganese | 0.3mm-5mm | 800mm-2250mm | Under 11000mm or Coil |

| 5052 | Aluminium and Mangesium | 0.3mm-5mm | 800mm-2250mm | Under 11000mm or Coil |