Both aluminum honeycomb panels and aluminum composite panels are popular materials in the construction and manufacturing industries, but there are some differences in terms of structure, properties, and applications. Here are some key differences between aluminum honeycomb panels and aluminum composite panels for your reference:

- 1. Different Composition

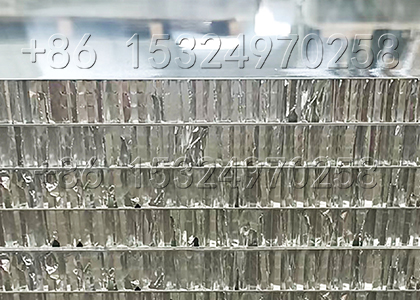

Aluminum Honeycomb Panels consist of two thin aluminum sheets bonded to a core made of hexagonal aluminum honeycomb cells. The honeycomb structure provides strength and stiffness while keeping the panel lightweight.

Aluminum Composite Panels are also called ACPs. They typically consist of two thin aluminum sheets bonded to a non-aluminum core, which is often made of polyethylene (PE) or a fire-resistant material. The core provides additional rigidity and insulation.

- 2. Different Weight

Honeycomb panels are known for their exceptional strength-to-weight ratio. They are lightweight due to the honeycomb core structure.

ACPs are also lightweight, but their weight may be higher compared to honeycomb panels, especially in applications requiring higher rigidity.

- 3. Different Strength and Rigidity

Aluminum Honeycomb panels offer high strength and rigidity. These properties make them suitable for applications where structural integrity is crucial. ACPs are strong and rigid. They may not match the structural strength of honeycomb panels in certain demanding applications.

- 4. Different Thermal Performance

The honeycomb structure provides natural insulation, and these panels may have better thermal performance compared to some ACPs.

Aluminum Composite Panels may have varying thermal properties depending on the core material. Fire-resistant cores can provide improved thermal resistance.

- 5. Different Flexibility

Aluminum Honeycomb panels may be less flexible than ACPs due to their rigid structure.

ACPs are more flexible and can be easily bent or shaped. That makes them suitable for curved surfaces and creative architectural designs.

- 6. Different Applications

Aluminum Honeycomb Panels are commonly used in aerospace, marine, and high-end architectural applications where lightweight strength is critical.

Aluminum Composite Panels are widely used in architectural cladding, signage, interior design, and other applications where a balance of cost, durability, and aesthetics is important.

When choosing plates between aluminum honeycomb panels and aluminum composite panels, it’s crucial to consider the specific requirements of the project, such as structural demands, weight considerations, cost constraints, and aesthetic preferences. Each material has its advantages and is suitable for different applications.